- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: xuzhou

- Brand Name: fangling

- Model Number: FJ1525

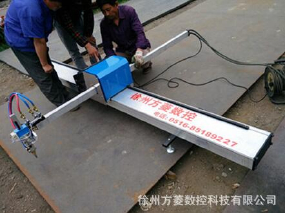

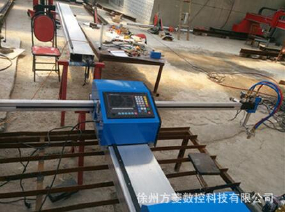

Brand Xuzhou diamond model FJ1525 type AC plasma welding machine

Automatic control mode of current AC control

Metal plate cutting frequency band high-frequency plasma source

Maximum cutting thickness 200 (mm) frequency 50 (Hz) input voltage 220 (V)

Power 150 (W) specifications 1500*2500

Our company's production of CNC equipment factory

Strictly do the diagonal line test, to ensure that the accuracy of each device cutting error control within the scope of 0.2MM. Please rest assured to buy.

Product parameter information

The configuration of CNC equipment flame cutting torch = flame cutting

Plasma cutting machine configuration CNC cutting machine arc pressure controller plasma = flame plasma

Cutting thickness flame: perforation thickness: 5-50MM, edge 5-200MM

The main configuration of the system: Shanghai Jiaotong university,

Software: FASTCAM expert set of material.

Driver: Shenzhen Lei Sai stepper motor drive,

Motor: Japanese letter of concentrated stepper motor

Relay: Japan OMRON switching power supply: Foxconn factory of switching power supply

24V DC motor for electric control device

Lifting adjusting device:

Lifting control device: the lifting device for the best counterparts, the use of DC

The motor drives the cutting torch lifting, the key parts of the influence of cutting precision: choose screw guide rod lifting mechanism

On imported rails, so as to ensure the stable and reliable operation of the vertical direction

Lifting mechanism for flame and plasma cutting torch cutting

Full copper inlet solenoid valve

Principle: power, the electromagnetic force to open the pilot hole, the chamber pressure to drop rapidly in close formation around the lower parts of high pressure, fluid pressure to promote the closure of parts moving up, the valve open; power, the spring force of the pilot hole closed, entrance pressure chamber through the bypass hole quickly formed under low. The high pressure around the valve off, fluid pressure to promote the closure of parts moving down, close the valve.

Equipment track, we use the thickening of all aluminum high-pressure molding, to ensure that the life will never be deformed. What if other manufacturers can contrast.

High voltage and high voltage, connection, plasma power supply! To achieve plasma cutting is so simple

Especially for non-ferrous metal (stainless steel, aluminum, copper, titanium, nickel) cutting effect is better; the main advantage is that when a small thickness of metal cutting, plasma cutting speed, especially in the ordinary carbon steel plate cutting, cutting speed of oxygen method 5~6 times, cutting surface smooth, small thermal deformation, almost no heat affected zone

- Place of Origin: xuzhou

- Brand Name: fangling

- Model Number: FJ1525